STEC 520

As the newest and most performing member of our controllers’ family, STEC 520 can operate in two different ways, based on the customer’s needs: operational modes programming (preinstalled operations), and free programming, with the possibility to save up to 999 different mould programs.

Safety above all

The collision detector of XW-VI Series STEC520 controller detects forthcoming collisions with other objects and immediately stops the robot. Up to 5 levels of detecting and sensitivity can be selected. Moreover, the vibration control system controls vibrations on the vertical axis for the optimal operation of the unloader, thus permitting an increase of smooth movements at high speeds and increased stability at extraction time.

Energy saving

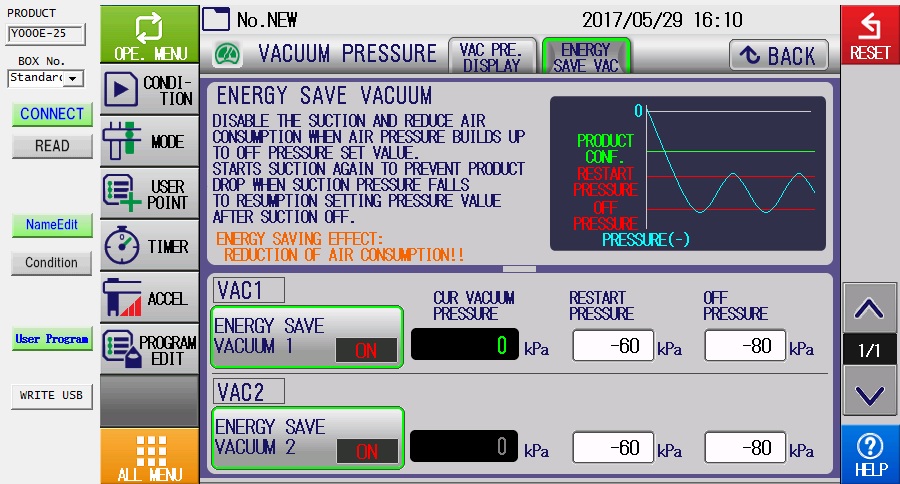

Thanks to our Eco mode, you will be able to save up to the 25% of electricity consumption in case stand-by times exceed the set ones, with the temporary stop of the servo motor and the turning off of the pendant background light. The automatic interruption of air supply to the vacuum generator allows a huge air consumption saving from the product collection with the suction cup to its deposit on the conveyor.